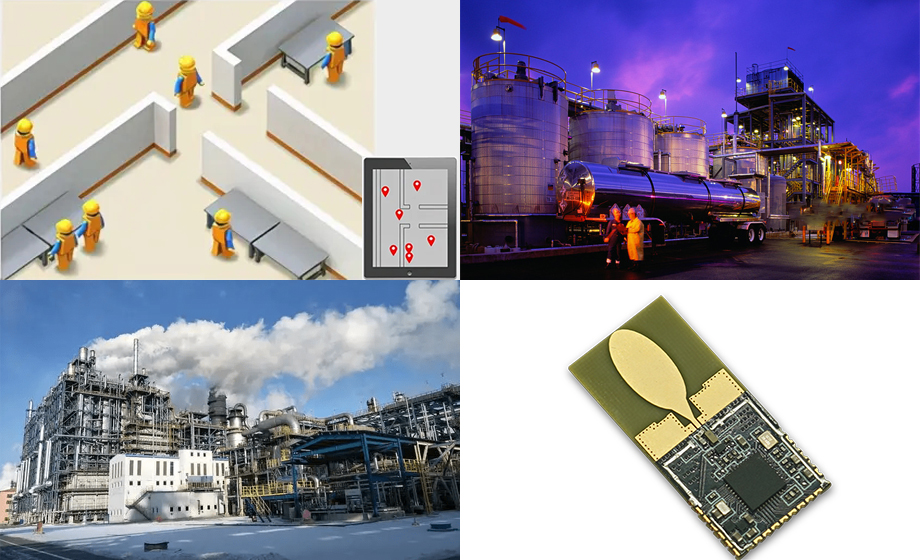

Industrial Internet UWB personnel positioning module Chemical plant personnel positioning. With the start of the construction of "Industrial Internet+Dangerous Chemical Safety", the safety management of chemical enterprises has paid more and more attention to various personnel safety management systems, including the personnel positioning system with the positioning technology as the core, such as the UWB personnel positioning module and Bluetooth. So, what functions can the personnel of such chemical plants realize in industrial safety management?

Real time chemical positioning

The core function of the personnel positioning system is reflected in the real-time and accurate positioning of personnel and materials. When checking in the chemical industry park, wear positioning labels to achieve real-time and accurate positioning of personnel and materials. Real time positioning is the basic logic of all personnel positioning systems, and all other important functions need to be based on high-precision real-time positioning.

Electronic fence

Electronic fence is an important function to realize the safety management of personnel positioning system. Different service providers use electronic fences differently. UWB takes the positioning system as an example. According to the needs of the enterprise, electronic fences of various shapes are drawn in key areas. The UWB personnel positioning module combines the real-time positioning function. When the operator approaches the electronic fence, overtime, intrusion and approaching alarms will be triggered, and the management personnel will be notified in a timely manner, providing an important guarantee for personnel safety management.

Historical track

The historical track function is mainly used to record the historical track of personnel and vehicles, facilitate the analysis of personnel behavior and event tracing, and provide data support for safety management.

SOS one button alarm

In case of emergency, field staff can give an alarm through the label SOS button on the label. After receiving the signal, the management personnel can quickly locate the position of the alarm personnel through the UWB personnel positioning module, check the on-site situation through the linkage monitoring video, and take emergency measures.

Intelligent access control joint defense

Access control system is an important security barrier for enterprises. The access control equipment is installed at an important position in the factory. The system is connected to the original access control system of the factory to realize the intelligent joint defense of access control. The system supports access control quantity statistics and regional access control distribution query. The credit card record details of each access control device can be retrieved, and the number and detailed list of personnel in each area can be counted.

Vehicle positioning

The vehicles to be located in the plant are equipped with positioning equipment of the uwb personnel positioning module. The system background monitors the vehicle position in real time and displays it on the three-dimensional map. Vehicle positioning can be linked with video monitoring and historical track playing.

In chemical enterprises, the safety management of chemical workers is the top priority. With the development of Internet of Things, artificial intelligence and other technologies, relying on the new technology UWB integrated positioning technology, integrating the safety control system network of personnel and equipment, to achieve high-precision real-time positioning of chemical plant personnel positioning, to achieve the safety control platform of personnel safety, personnel management, material management and vehicle management, and to help chemical enterprises transform intelligently.

The personnel of the chemical plant explained the equipment status and fault monitoring in detail. In the high-risk wilderness such as chemical industry, accidents often occur in the operation of equipment due to equipment faults. In the traditional manual inspection, the monitoring of equipment is not completely accurate. In order to eliminate the safety risks caused by equipment failures, enterprises urgently need new means and technologies to achieve early warning. The high-precision positioning system of the uwb personnel positioning module integrates the equipment data into the personnel positioning of the chemical plant through the deployment of the chemical park positioning system to achieve real-time monitoring, ensure the safe and stable operation of equipment, reduce safety risks and provide industrial benefits.

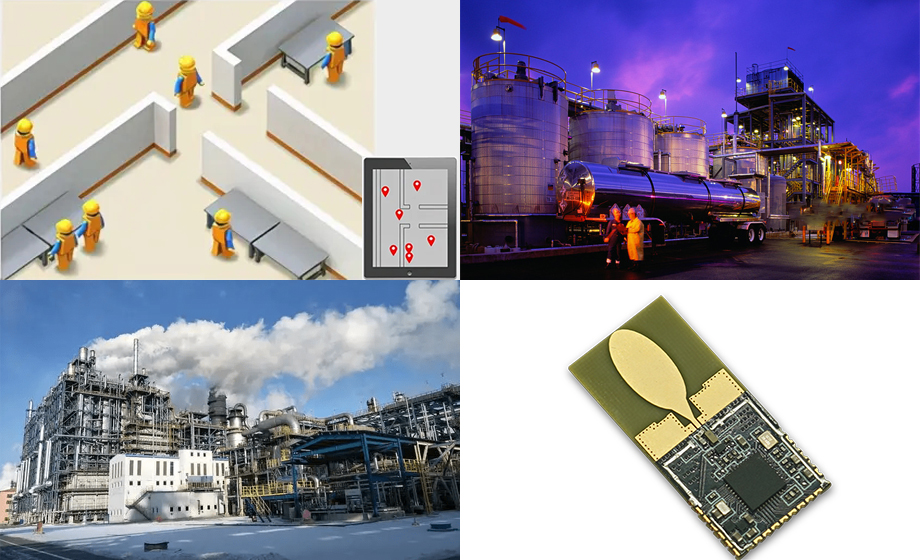

How to realize major equipment monitoring? As the focus of the current industry, the safety production of chemical plants has changed the traditional chemical control mode by using technologies such as the Internet of Things, 3D visualization, artificial intelligence, big data analysis, etc., and has realized the technology of positioning personnel, equipment, and vehicles in the chemical industry. The activity track of all personnel in the plant can be monitored through the full coverage of UWB positioning base stations and labels worn by personnel, Provide effective security guarantee for intelligent inspection of large equipment.

The personnel positioning of the UWB chemical plant can also monitor the equipment status and fault warning. The chemical positioning UWB system integrates the chemical monitoring system. With audio data as the core, supplemented by other equipment parameters, it builds an early fault prediction model based on the intelligent information system, that is, the physical information prediction model and the data information prediction model, which are determined according to the equipment operation status development parameters and characteristic models, state development standards and conditions.

Adopt the personnel positioning module technology of the chemical plant, based on the three-dimensional modeling digital twin technology, to visualize risks, hidden dangers, violations, equipment parameters, etc., to provide data support for the safe production and fine management of the chemical plant. The AI video monitoring system will combine the uniqueness of the location tag ID with the AI camera's ability to independently judge abnormal behaviors, improve the monitoring of equipment operation status, and realize the automatic monitoring of equipment status.

The high precision positioning system of the uwb personnel positioning module and the personnel positioning application scheme of the chemical plant. With the application of the Internet of Things technology in the power, chemical, coal and other industrial fields, the high precision indoor personnel positioning realizes the real-time positioning of personnel in the area. At present, there are many technologies on the market that can realize real-time positioning. The 10cm high-precision positioning UWB technology realizes the construction of personnel positioning and personnel security management system in the chemical industry park by deploying positioning base stations and positioning labels.

How to realize the personnel safety management in the chemical plant? The chemical production process is complex, and dangerous chemicals are flammable and explosive. A little carelessness will lead to major accidents. In recent years, the state has paid more and more attention to the safety supervision of chemical enterprises, and relevant laws and regulations have been issued, including the requirements for the "personnel positioning" of industrial Internet+hazardous chemical safety production.

In the traditional personnel safety management of chemical plants, managers cannot grasp the real-time position and dynamics of dangerous operators in real time, lack more comprehensive supervision on high-risk operations, and some outsourced operators have low sensitivity to some hazards, which may cause safety risks.

According to the needs of scene positioning in the chemical industry park, UWB introduced high-precision personnel real-time positioning technology to provide an effective solution. Through real-time positioning, the current position of personnel can be checked. The centimeter level high-precision positioning, combined with the electronic fence, can enter the dangerous area in time. Improper operation can avoid accident risks;At the same time, through the historical track function of the positioning system, you can also check the historical track of the operator, and timely and effectively find out whether there is missing inspection and missing inspection in the inspection management; In addition, the positioning system supported by positioning technology also includes more practical functions such as inspection management, attendance management and video access control integration, which can integrate the management system of employees involved in the enterprise, reduce redundancy and improve work efficiency.

Uwb personnel positioning module factory personnel positioning system realizes personnel safety management system in chemical high-risk work. At present, the chemical plant personnel positioning generally selects the UWB high-precision personnel positioning system to conduct safety management for on-site personnel. The system can accurately locate the real-time position of personnel, alarm key area problems, and provide effective technical support for personnel safety management. Similarly, the personnel positioning system of chemical plants in power plants, coal mines and other enterprises can be more standardized and strict.