The personnel positioning module solution of the mining uwb high-precision positioning system has made miners' accidents as fierce as tigers. Although various corresponding safety policies and regulations have been issued, miners' accidents occur from time to time. The key point is that there are loopholes in personnel safety management, causing various safety accidents. Although the mining enterprise has fully established the access control system and the fire control system through the 24-hour monitoring equipment of the transportation inspection control platform, the entire system does not have a personnel positioning system. The mine uwb high-precision positioning system technology, combined with big data, Internet of Things and other technologies, is used to provide the miners with real-time positioning, and effectively eliminate hidden dangers by checking operation data.

What functions does the positioning module of mine uwb high-precision positioning system factory personnel realize:

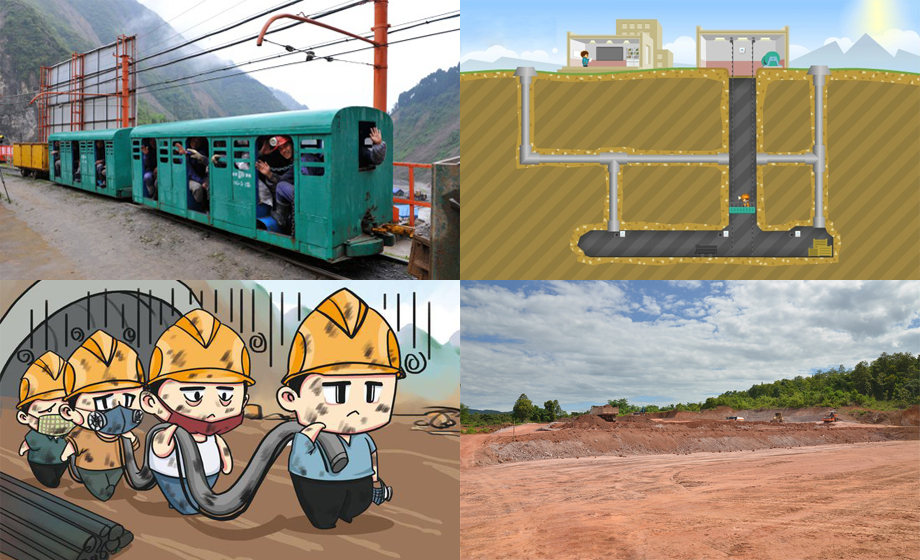

1. Personnel management: the distribution status is clear at a glance, which is convenient for managers to master the real-time dynamics of plant personnel;

2. Attendance management: automatically count the time and working conditions of employees in the area, and generate attendance reports, which is efficient and convenient;

3. Area management: the hazardous materials are separated from the area by dividing the electronic fence. Some personnel are close to the restricted area or have no right to enter the high-risk area, and the system triggers the cross-border alarm prompt;

4. Inspection management: the personnel positioning system of the mining uwb high-precision positioning system can be linked with the inspection system to improve the controllability of the inspection, and the recorded track can be replayed, providing a basis for the later review work. Through inspection and management, effectively realize dynamic, intelligent and standardized troubleshooting of hidden dangers, and reduce the incidence of accidents;

5. Behavior management: The positioning tag in the personnel positioning system of the mining plant supports the monitoring of behaviors such as overstaffing, off-duty, staying and overtime, and the system alarm prompt will be triggered immediately in case of any abnormality, which is convenient for correcting the non-standard operation behavior of workers in time and realizing the safety management of the plant area.

The solution of the personnel positioning module of the mining uwb high-precision positioning system is explained in detail. With the technology as the core and the combination of software and hardware, the UWB fully realizes the high-precision positioning of the mining plant employees, 2D/3D real-time display pictures, tracking and playback of action tracks, electronic fences in dangerous areas, paging alarm, video monitoring and positioning track linkage and other functions.

The personnel positioning of the mining plant makes up for the weaknesses and threats of the existing system, improves the timeliness and accuracy of the factory's business decisions, improves the intelligent level and operation efficiency of the enterprise, and provides a strong guarantee for the safe and stable operation of the mining enterprise.

How to improve the safety production control level of factory personnel? Once a safety accident occurs in the factory, the consequences are unimaginable, and the safety responsibility is more important than Taishan. The intelligent upgrading of the factory is an important step to promote the digital construction. The mine uwb high-precision positioning system is used for the positioning of factory personnel, and the industrial park is positioned and deployed. For enterprises, management can be strengthened Reduce personnel costs and better realize safe production. For employees, having such technology also improves work efficiency and ensures personal safety. Therefore, no matter which side, the intelligent factory worker positioning module system is beneficial to the security control of the enterprise.

Difficulties in enterprise safety production:

1. Difficult security means: the monitoring system has a dead space, which has great limitations on security protection and post disaster rescue.

2. Difficulty in personnel inspection: the workshop often has irregular behaviors such as overstaffing, understaffing and leaving the work area without permission.

3. Difficulty in regional control: there are many problems in personnel inspection, and there are frequent missed inspections, laying hidden dangers for the safety production of the factory.

4. Dangerous rescue: When employees are in danger, they often cannot grasp their specific location information and miss the rescue opportunity.

Functions of factory personnel positioning module safety management system:

1. Alarm management:

The on-site personnel can send SOS alarm information to the system through the positioning tag button, and give real-time alarm;

In case of any abnormality (such as coma), the tag card will automatically send alarm information to the system to ensure timely rescue.

2. Hot work management:

When fire operations are required, operators and information can be quickly bound to the system. According to the limited scope of activities in the workplace, fire can only occur within the specified scope. Once the scope is exceeded, the system will alarm to prevent major hazards. After the fire operations are completed, personnel and tags can be quickly unbound.

3 Overcrowding management:

The number of people in key areas is limited, and key areas and people can be set freely. Once the number of people in a certain area exceeds the set number of people, the mine uwb high-precision positioning system will alarm.

4. Electronic fence:

The personnel positioning module can flexibly set various rules, fences with different shapes in multiple areas, key areas such as the main control room, etc. Unauthorized personnel are not allowed to enter. Once the boundary crossing behavior occurs, the system will give an alarm immediately.